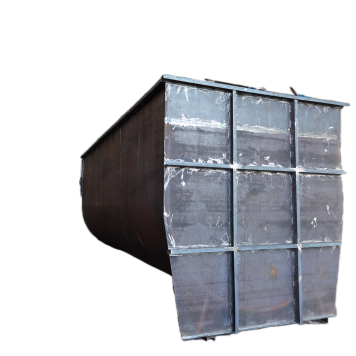

We manufacture various types of pressure vessels custom-made for a wide range of applications. Our product range includes air receivers, surge tanks, accumulators, blow-down tanks, flash tanks, expansion tanks, filter vessels, distillation columns, hot water generators, hydro pneumatic tanks, nitrogen storage tanks, LP heater assembly, propane tanks, propane dispenser tanks, pressure vessels, refrigeration vessels, horizontal ammonia receivers, vertical ammonia receivers, oil pots, scrubbers, separators and more. With adherence and conformance to national and international codes of design and fabrication, our equipment’s supplied for shore as well as offshore. Steel is purchased directly from renowned manufacturers all over India to get the best competitive rates. For small quantities and quicker deliveries, we also purchase steel from our reliable and well-established traders and stockiest, who can deliver plates of approved and recognized steel manufacturers, in a wide range of thicknesses with a minimum lead time of 1 or 2 days.

Applications of Pressure Vessels in the Industry: Pressure vessels are used in many different industries, but 3 industries cover most of the market. These industries are the oil and gas industry, chemical industry, and energy industry.

In the Oil and Gas industry, a pressure vessel is often used as a receiver where physical and chemical processes take place at high temperatures and pressures.

Although the columns are used for different purposes, they are similar in construction. Distillation columns are used to divide feed streams or streams into multiple sources, based on feed part boiling points. In general, pressure vessels and columns are purchased from the same manufacturers because of their similar construction processes. Carbon steel and stainless steel are the two most commonly used materials for construction in the oil & gas industry. A pressure vessel also requires other components in addition to the external body to become usable, such as vessel internals, and distillation trays. Such components are highly complex and they require specifications that are very different from those necessary for the manufacture of pressure vessels that are supplied by specialist suppliers.

It is a pressure vessel in which a process (chemical reaction) is carried out, which leads to a fundamental change in the content of the container.

These can be processes such as combining one or more products to create a new product, dividing one product into one or more different products, or removing directions of an existing product to create something else. Also, many different types of pressure vessels can be used simultaneously in the chemical industry.

There are a number of different causes of why the energy sector needs pressure vessels overall. One of the main reasons why they are needed within the energy sector is to contain harmful gases.

Often in places such as oil refineries as well as metalwork, excess gas needs to be stored. Also, Nuclear power plants use special pressure vessels named Reactor Pressure Vessels (RPVs). RPVs are large cylindrical steel vessels containing a core, cooling water, and generating steam, they require high reliability to withstand high temperatures and high pressures, and neutron irradiation, which makes the RPV the most critical pressure boundary in the nuclear power plant. But keep in mind, not all power reactors have a reactor pressure vessel.

• Autoclaves

• High-Pressure Vessels

• Expansion Tanks

• Heat Exchangers

• Water Pressure Tanks

• Vacuum Tanks

• ASME Pressure Vessels

• Thin-Walled Pressure Vessels

• Boilers

Get A Free Quote For Manufacturing & Fabricating

Contact us at the Industrial nearest to you or submit a business inquiry online.

Contact Us